|

zhangjiagang city benk machinery co., ltd.

|

| Price: | 85000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

PVC imitation marble sheet machine

pvc imitation marble sheet making machinery

PVC Imitational Marble Sheet/Board Making Machine(PVC artificial marble decorative plate production line, PVC artificial marble decorative sheet production line ) mainly produces the products: high UV light decorative board, stone plastic decorative board, PVC stone plastic flooring, PVC imitation marble decorative plate and PVC carved decorative board.

Advantages of PVC Artificial Marble Board

1, Environment friendly

2, Recycled available

3, Water proof

4, Anti-corrosion

5, Deformation hard .

PVC Artifical Marble Board: 1-8mm(thickness),1220*2440mm(standard width and length)

Flow of chart of producing

Crusher (crushing the edge of board trimmed) → Miller (milling the scraps into powder → Mixer (mixing the main materials and additives) → SJSZ 80/156 conical double Screws Extruder → Mould → Lamination unit → Three-calender unit → Cooling Bracket → Hual-off Machine → Edge Cutting → Cutter → Stacker → UV coating machine(choose need or not)

machine list:

PVC raw materials Loading and Mixing system | |

1. Spiral Loader or Vacuum auto Loader | 1 set |

2. High speed Heating Cooling Mixer unit | 1 set |

PVC marble sheet Extrusion Line | |

1. Spring Loader or Spiral Loader | 1 set |

2. SJZ80/156 Conical double screw Extruder | 1 set |

3. Mold/Die head Set | 1 set |

4. Three-roller Calander with Marble film unit | 1 set |

5. Temperature controller of three rollers | 1 set |

6. Cooling frame with side cutting | 1 set |

7. Haul off unit | 1 set |

8. Cutting unit | 1 set |

9. Stacker | 1 set |

Sheet/Plate Recycling machines | |

1. Sheet Crusher/Grinder | 1 set |

2. PVC Pulverizer/Miller | 1 set |

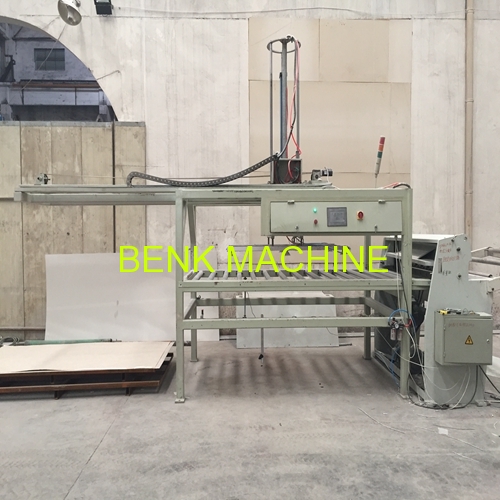

reference pics from client factory:

whole line

lamination device:

automatic unloader device:

main technical parameter:

| main extruder | SJZ80/156 conical double screw extruder |

| board size | 1220mm wide, 1-8mm thickness |

| output | 350KG/H |

| main motor | 75KW SIEMENS motor |

| inverter | ABB |

| instlaltion power | 195KW |

| installation size | 22X4X3.5M |

3, BENK's Service:

3.1 Technical documents

All the symbols on the equipments should be in English. Seller is responsible to provide general layout plan, electric plan, installation direction, and manual book in English to Buyer on time.

3.2. Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. BENK will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 per day for each engineer.

d. Engineer will give free training lessons to labors in buyer's factory.

e. If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

3.3. Quantity and quality guarantee

a. Quantity/Quality Discrepancy to destination port during transportation:

In case of quality/quantity discrepancy to destination port in transportation, customer should file claim within 30 days after the arrival of the goods at port of destination. Insurance company and shipping company will be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.

b. Guarantee period and after-sales services: 13 months since date of bill of loading

During this guarantee period, BENK will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, BENK will provide the buyer spare parts at cost price.

c. Long-term service:

BENK will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

We thank you for your inquiry and would be pleased to receive your order soon.

ZHANGJIAGANG CITY BENK MACHINERY CO., LTD.